Silicate modified polyurethane material

for coal mine reinforcement coal rock mass

Product Description:

The silicate modified polyurethane material for coal mine reinforcement coal rock mass is composed of component A and component B, component A is a uniform, non-stratified and non-agglomerated liquid, and the main component of the material is polyether polyol. Component B is a homogeneous, non-stratification, non-agglomerating liquid, the main components of which are polyether polyols and isocyanates. The consolidated body formed after mixing and curing of component A and component B according to the volume ratio of 1:1 has the characteristics of high mechanical properties, can effectively cement the original loose, broken and discontinuous coal and rock mass into a continuous and complete consolidated body, and can enrich the fracture space of coal and rock mass, change the stress distribution of coal and rock mass, and improve the load-bearing capacity of coal and rock mass. Quickly solve all kinds of formation problems with potential safety hazards. Prevent accidents such as roof crushing and roof rising, and ensure production safety. Easy to use can effectively simplify the construction process, save construction time and reduce construction costs.

Specifications and models:

Model: JG PU SixOy

Meaning: JG stands for the use of coal and rock mass reinforcement;

PU SixOy stands for material property and is a polyurethane material.

Technical Indicators:

|

Serial number |

Project |

Index |

|

|

1 |

Curing time,s |

180±20 |

|

|

2 |

Maximum reaction temperature,℃ |

≤100 |

|

|

3 |

Expansion multiple, multiple |

≥1.0 |

|

|

4 |

Oxygen index,% |

≥28 |

|

|

5 |

Anti-aging properties |

There is no change in the surface, and the compressive strength is lost≤5% |

|

|

6 |

Alcohol blowtorch burning experiment |

The average burn time of the flame,s |

≤3 |

|

The maximum burn time of the flame,s |

≤10 |

||

|

The average amount of flameless burning time,s |

≤10 |

||

|

The average amount of flameless burning time,s |

≤30 |

||

|

Maximum flame extension length,mm |

≤280 |

||

|

7 |

Alcohol lamp burning experiment |

The average burn time of the flame,s |

≤6 |

|

The maximum burn time of the flame,s |

≤12 |

||

|

The average amount of flameless burning time,s |

≤20 |

||

|

The average amount of flameless burning time,s |

≤60 |

||

|

Maximum flame extension length,mm |

≤250 |

||

|

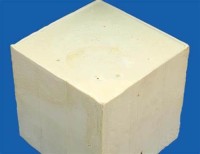

8 |

compressive strength,MPa |

≥40 |

|

|

9 |

tensile strength |

≥5 |

|

|

10 |

Shear strength |

≥15 |

|

|

11 |

Bond strength |

≥3.0 |

|

|

12 |

Maximum Reaction Temperature (Simulated Construction Process),℃ |

≤120 |

|

|

When the pressure is 40MPa, the shape of the test block becomes (45±10)%。 |

|||

Performance characteristics:

Silicate modified polyurethane material for coal mine reinforcement coal rock mass has the following characteristics:

(1) High strength, good toughness and deformability;

(2) Strong and durable adhesion, fast, simple and convenient construction;

(3) Good flame retardant performance.

Main uses:

The material is mainly used for grouting reinforcement of underground broken coal and rock mass, which can quickly and effectively improve the bearing capacity of coal and rock mass and ensure the safety of mining. It is mainly used in the following aspects:

◎ Roadway broken roof and wall reinforcement;

◎ Coal wall sheet of the mining face is advanced treatment for the roofing;

◎ Advanced reinforcement of roadway roofs, faults, fracture zones and collapse columns in soft coal seams

◎ Shimen coal removal, removal of the channel and reinforcement of thin coal pillars, etc

packaging:

Packing: Sealed packaging in plastic drums

Packing: 50kg/set, 24 kg for A component, 26 kg for B component.

After-sales service:

The company has an after-sales service department, which is responsible for collecting user feedback on the use of information, guiding users to use correctly, and solving problems in the process of use.