One-component modified epoxy adhesive

Product Features:

1. One-component modified epoxy adhesive, solvent-free, low odor, neutral and environmentally friendly.

2. Thixotropic paste, heating and curing without sagging, easy to use.

3. Excellent weather resistance, aging resistance, compatible with pretreatment fluids, electrophoresis fluids. Superior tensile and compressive recovery.

4. It does not require a primer and has excellent adhesion properties to materials such as aluminum and painted steel.

Product Description:

QLD568 Epoxy hemming glue

It is suitable for the folding of the inner and outer panels of the automobile door, the joint of the cab floor, the cab top cover, the trunk cover, the side wall, the wheel cover, the engine cover and other folding parts, which play the role of bonding, sealing, shock absorption and anti-rust.

QLD569 Toughened structural adhesive

It is suitable for body suspension beams, A/B/C column upper and lower ports, upper side beams, door frame beams, front and rear box locks and other parts or spot welded parts, which can be used for bonding, increasing body rigidity, impact resistance, fatigue resistance, and improving automobile safety performance.

Product performance

|

Product model |

568 |

569 |

|

Appearance of the compound |

Red paste |

Gray paste |

|

Density (g/cm) |

1.4±0.1 |

1.3±0.1 |

|

Pressurized viscosity (g/min) |

30~70 |

30~70 |

|

Non-volatiles (%) |

≥98 |

≥98 |

|

Solidification conditions (160~180℃,30min) |

Fully cured |

Fully cured |

|

Resistance to sagging (mm) |

≤3 |

≤3 |

|

Shear strength (MPa, 23℃) |

≥16 |

≥23 |

|

Heat aging resistance/water resistance/corrosion resistance/alternating heat and cold (MPa) |

≥15 |

≥18 |

|

Tear strength (N/mm) |

≥2 |

≥4 |

|

Cures the appearance |

The surface of the adhesive layer is not sticky, no cracks and bubbling, dense and no bubbles |

|

|

Project |

Total carbon volatilization |

Smell |

Atomization value |

Aldehydes |

Benzene series |

|

|

Enforce the standard |

VDA277 |

VDA270 |

DIN75201 |

VDA275 |

VDA277 |

|

|

Standard value (≤) |

50μgC/g |

3.5级 |

5mg |

10μg/g |

5μg/g |

|

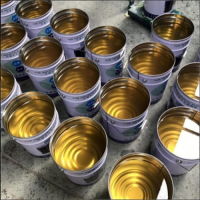

Packing specifications

|

Plastic cylinders |

300ml |

|

Plastic cylinders |

25kg |

|

Tin bucket |

250kg |

Usage

1. The gluing surface should be free of oil stains, dust, impurities, etc.;

2. According to the process requirements, the paint will be evenly sprayed, and the thinnest part is greater than 1mm; When using a pneumatic gun, the air pressure is controlled at 0.2-0.4Mpa;

3. Curing process: 160~180°C for 30min, it can be completely cured;

4. After curing, the product can be trimmed using traditional methods.

Precautions

1.Avoid applying it in an environment below 5℃

2. It must be stored in a low temperature and dry environment with a shelf life of 3 months.