one-component epoxy structural adhesive

u Technical Data Table

|

Performance |

5531 |

5532 |

|

Appearance A/B |

White thixotropic paste |

Black thixotropic paste |

|

Viscosity(pa.s,25℃)) |

80~150 |

80~150 |

|

Curing conditions |

120℃30min |

120℃30min |

|

Shearing strength(MPa) |

21 |

21 |

|

Volume resistance(Ω·cm,25℃) |

1.5×1015 |

1.5×1015 |

|

Surface resistivity(Ω,25℃) |

1.2×1015 |

1.2×1015 |

|

tensile strength(kg/mm2) |

13 |

13 |

|

compressive strength(kg/mm2) |

15 |

15 |

|

Hardness (shore D) |

83 |

83 |

|

Wire shrinkage (%) |

<0.5 |

<0.5 |

|

Heat deflection temperature (℃) |

>150 |

>150 |

u Features and Uses

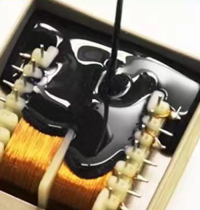

One-component epoxy structural adhesive is a medium-high temperature curing one-component epoxy adhesive. It has the characteristics of stable storage, high bonding strength, good insulation performance, easier to use than two-component, thixotropic and strong applicability when curing, and the cured object can be black or white solid. It is suitable for bonding metal, plastic, glass and other materials.

u Typical Applications

5531 one-component epoxy structural adhesive: White thixotropic paste

5532 one-component epoxy structural adhesive: Black thixotropic paste

u Operation process

1. Take the glue out of the refrigerator and put it at room temperature to balance with the outside world for 1~2 hours.

2. Spread the adhesive on both sides of the device to be bonded.

3. Heating and curing.

4. After use, the lid should be covered in time and stored in the refrigerator at 5°C.

u Notes

1. The validity period of this product is 3 months when stored at 5°C, and it can still be used if the viscosity is suitable after the storage period.

2. The curing test should be carried out according to the actual curing conditions and the characteristics of the processed components to ensure the best curing conditions suitable for specific products.

3. This product is non-dangerous goods, and it is stored and transported as non-dangerous goods.

4. Packing specification: 300mL/tube, 25 tubes/carton.