Low modulus silane sealant

uTechnical Data Sheet

|

Brand Number |

QLD939 slurry |

QLD939 semi-flow |

QLD939 flow |

|

Appearance |

Gray paste |

Gray semi-flow |

(Gray self-leveling) |

|

Sag (mm) |

≤2 |

≤6 |

-- |

|

Density (g/cm 3 ) |

1.4±0.2 |

1.4±0.2 |

1.2±0.2 |

|

Workbench drying time (min) |

20~50 |

20~50 |

20-50 |

|

Curing speed (mm/24h) |

2.0-3.0 |

2.0~3.0 |

2.0~3.0 |

|

Tensile strength (Mpa) |

≥0.7 |

≥0.5 |

≥0.4 |

|

Elongation at break (%) |

≥650 |

≥750 |

≥850 |

|

Elastic recovery rate (%) |

≥70 |

≥70 |

≥70 |

|

Tensile modulus (MPa) |

≤0.4 |

≤0.4 |

≤0.4 |

|

Fixed stretch bond |

No damage |

No damage |

No damage |

|

Temperature range (°C) |

-40~120 |

-40~120 |

-40~120 |

|

Packing Specifications |

2.6L/barrel , 25kg/barrel , 400ml/dual tube |

||

uFeatures and uses

This product is made of modified silane material, solvent-free, anti-pollution after curing, environmentally friendly, low modulus, high elongation, and has excellent heat resistance and anti-aging ability. This product complies with the environmental protection requirements of GB 33372-2020 "Limits of Volatile Organic Compounds in Adhesives" and complies with EU ROHS and REACH environmental protection standards. In order to meet the requirements of deep curing, 1:1 two-component sealants can be produced.

Typical Applications

QLD939Paste is a thixotropic paste used for sealing and bonding LED lamps, electronic components and electromechanical parts.

QLD939 semi-flow type , used for sealing, bonding and fixing of LED lamps and electronic components.

QLD939Flow self-leveling , used for sealing LED lamps, electronic components and electromechanical parts.

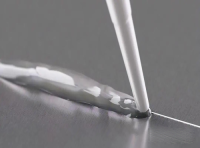

uOperation Process

1. The bonding surface should be free of oil, dust, impurities, etc.;

2. According to the process requirements, cut the glue nozzle into the required size and shape;

3. Cut off the sealant seal, install the nozzle, and insert the glue gun;

4. Apply the sealant evenly on the joints, with the thinnest part larger than 1mm; when using a pneumatic spray gun, the air pressure should be controlled at 0.2~0.4Mpa.

5. Once the product is dry, it can be repaired using traditional methods to remove excess glue.

uComments

1. Avoid construction in an environment with a temperature below 5°C and a humidity below 20%;

2. The pneumatic pressure shall not exceed 0.5Mpa. If this limit is exceeded, the gas will enter the hard packaging tube and produce colloidal bubbles;

3. Due to the high solvent content in the coating, the adhesive surface will become soft. In order to achieve the best appearance and performance, coloring should be carried out after the gel has cured for 24 hours;

4. Store in a sealed container in a cool and dry place for 6 months. It can still be used after the expiration date.